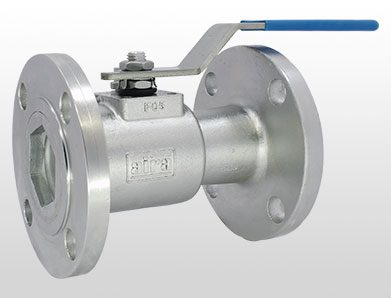

Are you looking for a reliable, cost-effective ball valve for your industrial piping system? If so, you should consider a single piece ball valve. Single piece ball valves are designed for maximum performance and reliability, and they offer a number of benefits for industrial applications. In this blog post, we’ll take a closer look at some of the advantages of using single piece ball valves in industrial settings.

Maximizing Performance and Reliability with Single Piece Ball Valves

There are many reasons why single piece ball valves are a good choice for industrial applications. They offer superior performance and reliability compared to other types of valves, and they are also easy to install and maintain. Single piece ball valves are available in a variety of materials, so they can be selected to match the application requirements.

One of the main advantages of using a single piece ball valve is that it offers superior performance. The valve is designed so that there is no leakage, even when the pressure is high. This means that you can rely on the valve to perform as expected, even in demanding applications.

Another advantage of using a single piece ball valve is that it is very reliable. Because there are no moving parts, there is less chance of something going wrong with the valve. If something does go wrong, it is usually easy to identify and fix the problem.

Single piece ball valves are also easy to install and maintain. They do not require special tools or skills, so they can be installed by anyone with basic DIY skills. Once installed, they require little maintenance and can provide years of trouble-free operation.

If you are looking for a valve that offers superior performance, reliability and ease of installation and maintenance, then a single piece ball valve is a good choice for your application.

Why Single Piece Ball Valves are the Best Choice for Industrial Piping Systems

There are many reasons why single piece ball valves are the best choice for industrial piping systems. First, they are incredibly durable and can withstand high pressures. This makes them ideal for use in industries where there are high temperatures and pressures, such as the chemical industry. Second, they provide a tight seal that prevents leaks. This is important in industries where products need to be transported through pipelines without leaking. Third, they are easy to install and maintain. This is important in industries where there is a need for quick and easy installation, such as the food and beverage industry. Finally, they are available in a variety of sizes and configurations to meet the needs of different industrial applications.

The Benefits of Using Single Piece Ball Valves in Process Control Applications

Single piece ball valves offer a number of advantages in process control applications. They are durable and provide a tight seal, making them ideal for regulating flow in process piping systems. Ball valves are also easy to install and maintain, and come in a variety of sizes and configurations to meet the needs of any application.

Single piece ball valves offer superior performance in process control applications due to their design. The one-piece construction of the valve body and internal components ensures that there are no potential leak points, providing reliable operation even under demanding conditions. The tight seal created by the ball valve design prevents process fluids from leaking out of the system, while still allowing for smooth and precise regulation of flow.

The ease of installation and maintenance is another key advantage of using ball valves in process applications. Unlike other types of valves, ball valves can be installed quickly and easily, with minimal training or experience required. Once installed, ball valves require little maintenance or upkeep, making them an ideal choice for busy facilities.

Ball valves are available in a wide range of sizes and configurations to meet the needs of any application. From small diameter valves for use in pilot lines to large diameter valves for use in mainlines, there is a ball valve size and configuration to suit every need. Valve manufacturers also offer a variety of material options for different process requirements, ensuring that there is a ball valve that can meet the demands of any application.

Maximizing Efficiency and Cost Savings with Single Piece Ball Valves

While single piece ball valves offer many advantages, they are particularly well-suited for maximizing efficiency and cost savings in industrial applications.

Ball valves are often used in process control systems to regulate the flow of fluids. By design, ball valves allow for a wide range of flow rates with minimal pressure drop. This makes them ideal for use in systems where it is important to maintain a constant flow rate, such as in manufacturing or food processing.

In addition, ball valves are very durable and can withstand repeated cycling without leaking. This makes them ideal for use in systems that require frequent shut-downs and start-ups, such as in power plants or refineries.

Finally, ball valves are easy to install and maintain. They can be replaced quickly and easily if they become damaged, which minimizes downtime and reduces maintenance costs.