How to Choose the Perfect Valve Manufacturer for Your Business

Valves are essential to many businesses, but finding the proper valve manufacturer can be challenging. When choosing a computer, it is necessary to consider a few factors of a valve manufacturer, such as the type of valves you need, the quality control offered, and the price. With so many options, how can you find the perfect valve manufacturer for your business?

You can help yourself by following these tips to choose the perfect valve manufacturer for your business:

1. Consider your needs

The first step is to consider your needs. What type of valves do you need? What are the specifications of the valves? Once you know what you need, you can start to narrow down your options.

2. Compare prices

Price is always a factor when choosing a valve manufacturer. You want to find a manufacturer that offers a competitive price without sacrificing quality.

3. Check the quality control

Quality control is essential when choosing a valve manufacturer. You want to ensure that the manufacturer has a good reputation for quality products and that they have a process to ensure that the valves meet your specifications.

4. Consider the customer service

The manufacturer’s customer service is also essential. You want to ensure they are responsive to your questions and concerns.

5. Get a sample

Finally, it’s always a good idea to get a sample of the valves before you make a purchase. This will allow you to test the valves and ensure they meet your needs.

By following these tips, you can be sure to find the perfect valve manufacturer for your business.

Why do you need a valve manufacturer?

A valve manufacturers is a company that designs and manufactures valves. Valves are used in various industries, including oil and gas, petrochemical, chemical, power generation, water treatment, food and beverage, pharmaceutical, and biotechnology.

Valves are an essential part of many process systems and control the flow of fluids (liquid, gas, or slurry) through pipelines. They are also used to regulate pressure and temperature within systems. Valves can be manual or automated and come in various sizes and shapes to suit different applications.

You may need a valve manufacturer for your business. If you have a process system requiring valves, you will need to source them from a manufacturer. Even if you already have valves installed in your system, you may need to replace them at some point due to wear and tear or damage. And if you are planning to expand your process system, you will need to purchase new valves from a manufacturer.

When sourcing valves from a manufacturer, it is essential to choose one that is experienced and reputable. The quality of the valves manufactured by the company will directly impact the performance of your process system. Poor-quality valves can lead to downtime and lost production due to leaks or blockages. So it is essential to research and choose a valve manufacturer with a good track record of manufacturing high-quality products.

What are the different types of valves?

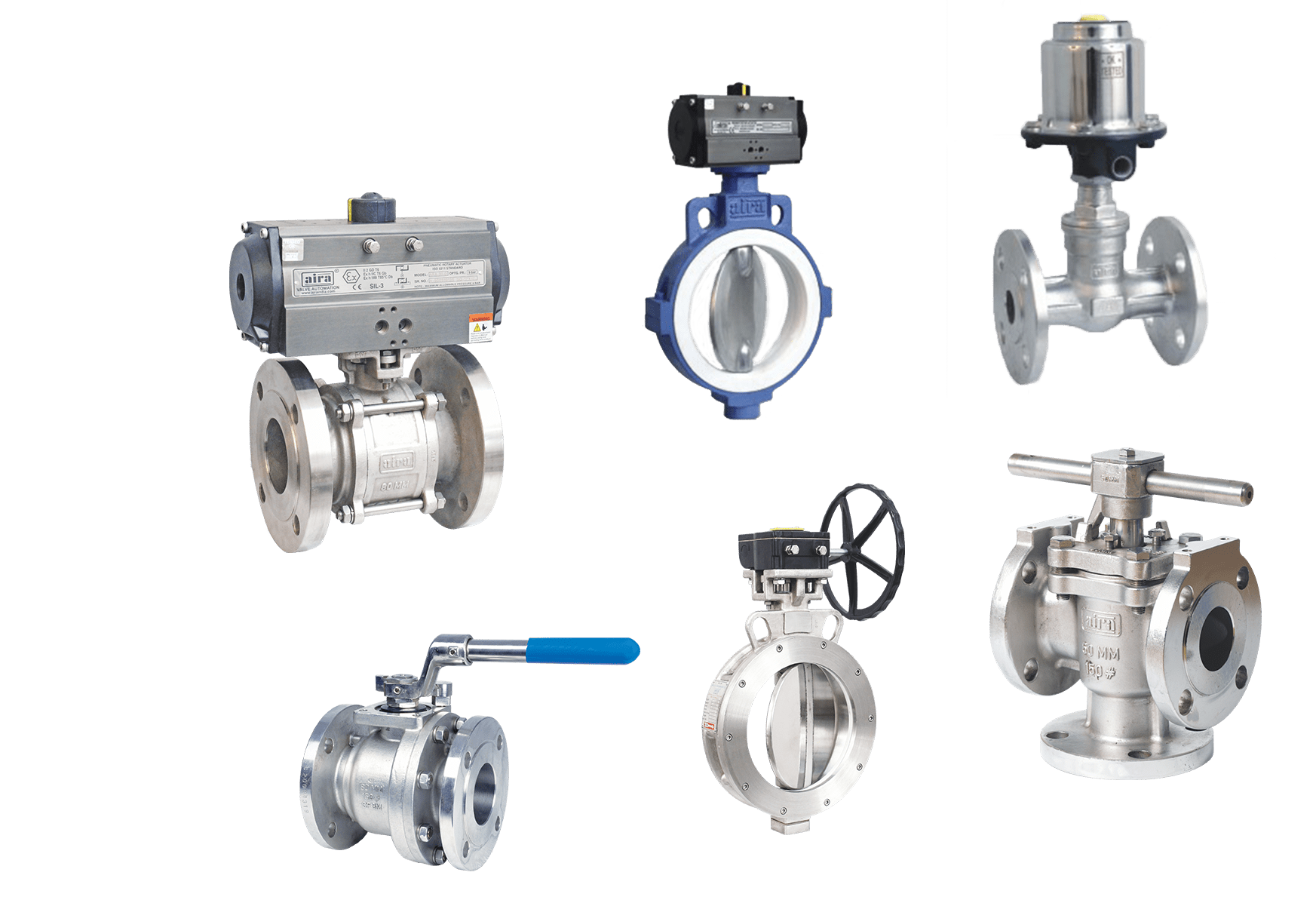

There are many different types of valves on the market, each with its advantages and disadvantages. The most common valves are ball valves, butterfly valves, check valves, diaphragm valves, gate valves, globe valves, and pinch valves.

Ball valves are the most popular due to their simple design and reliability. Ball valves consist of a ball with a hole in the center connected to a handle. When the handle is turned, the ball rotates to open or close the valve. Ball valves are available in both metal and plastic construction.

Butterfly valves are another popular type of valve. Butterfly valves consist of a disc that is connected to a shaft. The disc is opened or closed by turning the post. Butterfly valves are available in both metal and plastic construction.

Check valves that allow flow in one direction only and prevent backflow. Check valves are often used in piping systems to prevent backflow into pumps and other equipment. Check valves are available in both metal and plastic construction.

Diaphragm valves consist of a diaphragm that is actuated by a lever or handle. When the lever or handle is turned, the diaphragm opens or closes the valve. Diaphragm valves are available in both metal and plastic construction.

Gate valves allow for flow control in pipelines and consist of a raised or lowered gate to open or close the valve. Gate valves are available in both metal and plastic construction.

Globe valves consist of a globe that is actuated by a lever or handle. When the lever or handle is turned, the world opens or closes the valve. Globe

What are the factors to consider when choosing a valve manufacturer?

When choosing a valve manufacturer, there are several factors to consider. The most crucial factor is the quality of the valves. The valves must be made from high-quality materials and have a tight seal to prevent leaks. The manufacturer should also have a good reputation for customer service and delivery times. Another essential factor to consider is the price of the valves. The manufacturer should offer competitive prices without sacrificing quality.

How to find the proper valve manufacturer for your business?

There are a few key factors to consider when finding the proper valve manufacturer for your business. The most important factor is quality. The valves must be made of high-quality materials that meet your specifications. The manufacturer should also have a good reputation for customer service and delivery times. Another essential factor to consider is price. You want to ensure you get the best value for your money.

To find the proper valve manufacturer:

Start by doing some research online.

Read customer reviews and compare prices.

Once you have narrowed your options, contact the manufacturers directly and ask for quotes.

Specify your needs and ask about delivery times and customer service policies.

Choose the manufacturer that offers the best combination of quality, price, and service.

The benefits of working with a valve manufacturer

Businesses can expect high-quality valves to meet their needs when working with a valve manufacturer. The manufacturer should also have a good reputation for customer service and delivery times. Another essential factor to consider is the price of the valves.

Working with a valve manufacturer offers many benefits, including high-quality valves, good customer service, and reasonable prices. When choosing a valve manufacturer, it is essential to research manufacturers online and contact them directly to get quotes. Choose the manufacturer that offers the best combination of quality, price, and service.

The importance of quality control

Quality control is one of the most important aspects of choosing a valve manufacturer. The valves must be made to precise specifications to function correctly. In addition, the valves must be tested for durability and reliability. The manufacturer should have a good reputation for quality control to ensure that the valves meet the customer’s expectations.